Custom Cable Assemblies & Wiring Harnesses Manufacturer

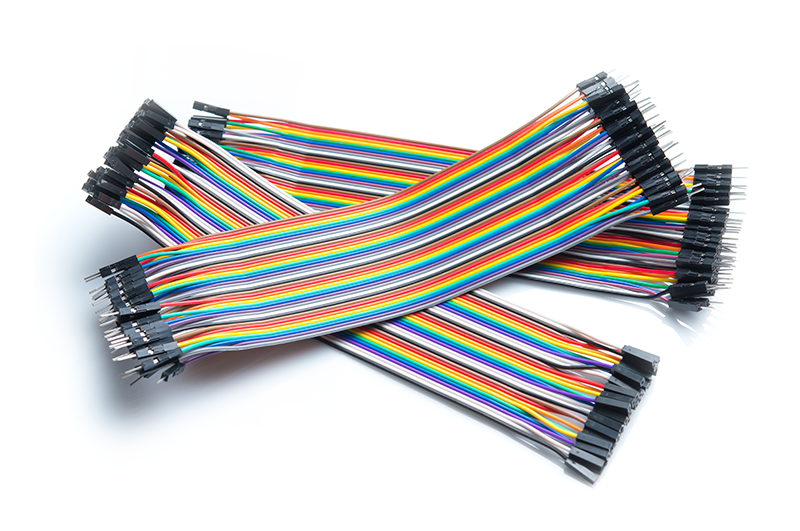

Custom Cable Assemblies

Inno Cables manufactures cable assemblies according to the designs of our customer specifications. These products enable businesses to develop reliable assemblies that meet their application’s unique needs.

Cable assemblies have the ability to improve operations and simplify systems across many consumer and commercial enterprises. It’s also possible to craft these assemblies using interconnect assembly, overmolding, insert molding or custom in-house tooling.

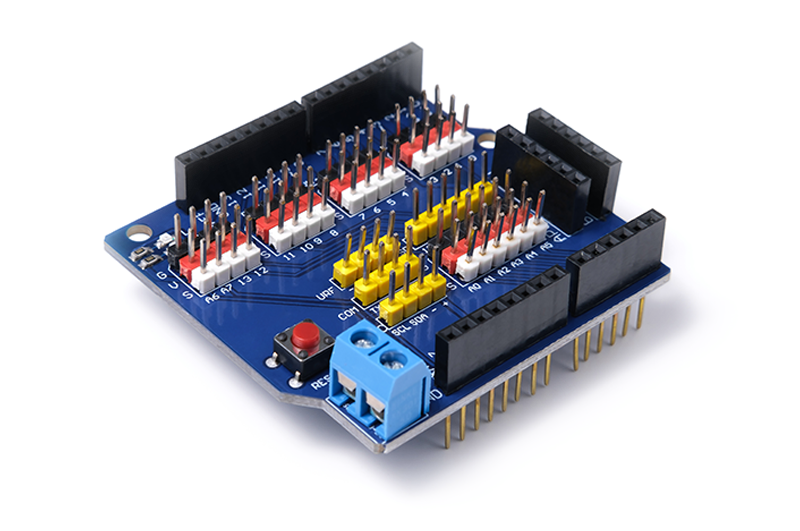

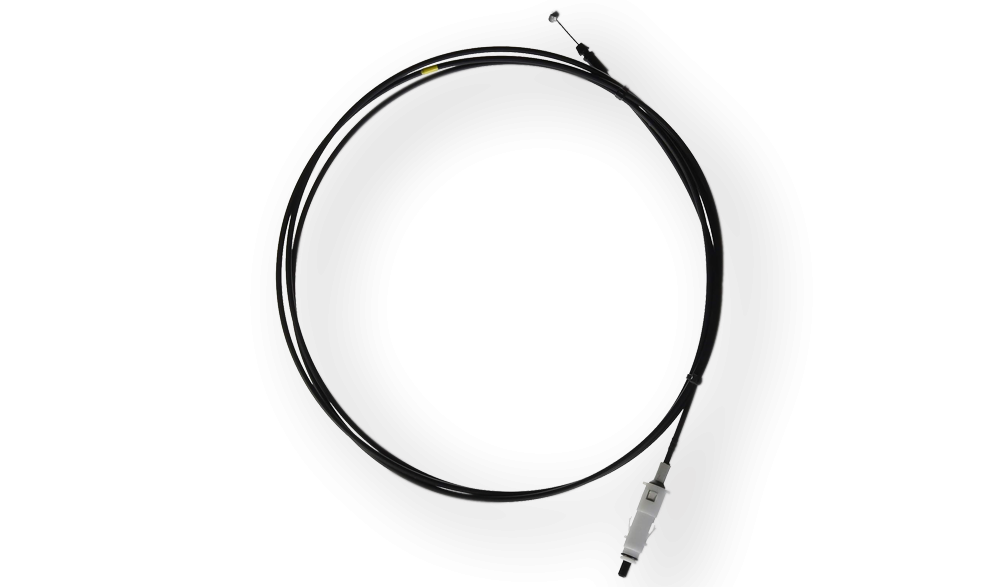

Custom Wire Harnesses

Wire harnesses provide a simple but reliable solution for reducing costs compared to other types of harnessing solutions that involve multiple complex elements. A dependable wire harness offers consistent insulation and provides protection for one or more conductors contained within.

The many advantages that wire harnesses offer stem from basic principles in their design. By combining multiple subassemblies, cables and wires into a harness, installers only need to install a single component. Wire harnesses provide sufficient protection against vibration and abrasion, along with added space by forming non-flexing bundles. Wire harnesses can go in multiple directions with several ends while simplifying more complex wire and cable systems.

At Inno Cables, we take a strategic approach to engineering wire harnesses, which enables us to choose the right connectors and shielding based on your application’s unique needs. We also account for all regulatory standards that apply in your industry to help make sure that every custom harness is consistently compliant, reliable, safe, and effective.

Understanding the Cable Assemblies & Wiring Harnesses Manufacturing Process

The custom Cable Assemblies & Wiring Harnesses manufacturing process consists of four main stages

-

Design. In the design phase, designers and engineers work closely with customers to outline their needs and constraints. These requirements and restrictions are used to create and digitally test potential designs.

-

Prototyping. In the prototyping phase, physical models of potential cable assembly designs are created. These units are used to test for functionality and manufacturability, ensuring they can be made and used as intended.

-

Production and Assembly. In the production and assembly phase, the cable assemblies are manufactured as per the approved final design in the desired volumes. The manufacturing process consists of many steps, including cutting the conductors, establishing their connections, and assembling them into a single wrapped jacket.

-

Testing. In the testing phase, the completed assemblies undergo rigorous testing to ensure they perform safely and effectively. The exact tests depend on industry and application requirements.

Our Advantages

Flexibility

We are able to provide customized solutions to meet your specific requirements, including unique designs, materials and configurations.

Quality

Standards

Speed

Competitive Pricing

Customer Service

If you have any questions?

If you have any inquiries or need more information about our wire harness products and services, please feel free to contact us.