Printed Circuit Board Assembly

A PCB cable assembly is a collection of cables designed for use with printed circuit boards. It comprises a group of 2 or more conductors bundled together and encased in a protective covering. The ends feature connectors or terminations, whose design can vary depending on the usage requirements.

PCB Cable Assembly Manufacturing

Our connected world has increased in technological advancements at an exponential rate and the need for both commercial and industrial PCBs has risen in lockstep. Not only do PCBs and cable harness assemblies need to be highly capable but getting these products into the hands of clients given the many supply chain restrictions seen today takes a proven supply chain management system in place.

At Meridian, we deliver these kinds of exceptional results every day with a full line of some of the most advanced manufacturing capabilities available. From prototyping runs to making sure every component comes together perfectly to massive volume manufacturing, PCB assembly along with the custom cable assemblies provides total box, as well as sub-assembly set-ups for even the most challenging circumstances.

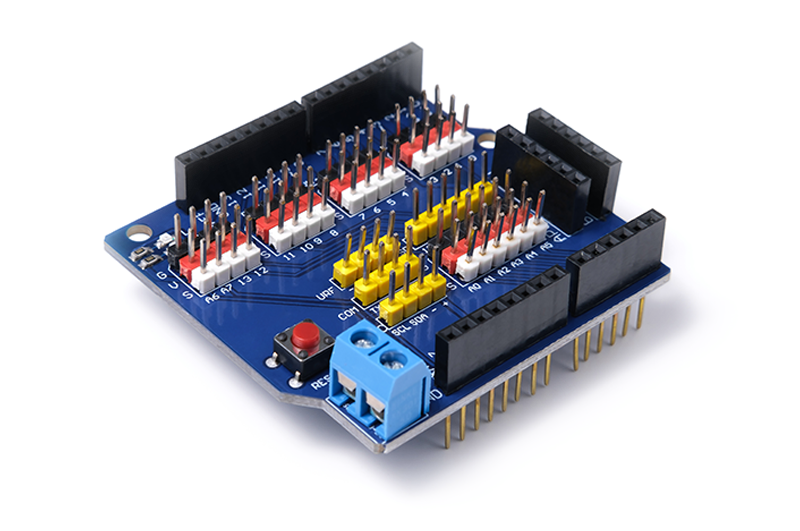

PCB assembly can take many different shapes, depending on the needs of the project. There’s flex PCBs and standard rigid boards, single boards, double boards, multiple layers, and even specialized aspects like through-hole printed circuit boards. All of these require a perfect set of design parameters and precise engineering to provide a useful final product that will easily integrate into its intended system.

What are the Advantages of PCB Cable Assemblies?

It Simplifies the PCB Assembly

Reduced PCB Manufacturing Costs

Increased PCB Adaptability

Enhanced Safety and Durability

What is a PCB Cable assembly Made Of?

Conducting Wires

Outer Covering/Sheath

Insulation

EMI Shielding

Connectors or Terminations

Understanding the Printed Circuit Board Assembly Manufacturing Process

The custom cable manufacturing process consists of four main stages

-

Design. In the design phase, designers and engineers work closely with customers to outline their needs and constraints. These requirements and restrictions are used to create and digitally test potential designs.

-

Prototyping. In the prototyping phase, physical models of potential cable assembly designs are created. These units are used to test for functionality and manufacturability, ensuring they can be made and used as intended.

-

Production and Assembly. In the production and assembly phase, the cable assemblies are manufactured as per the approved final design in the desired volumes. The manufacturing process consists of many steps, including cutting the conductors, establishing their connections, and assembling them into a single wrapped jacket.

-

Testing. In the testing phase, the completed assemblies undergo rigorous testing to ensure they perform safely and effectively. The exact tests depend on industry and application requirements.

At Inno Cables have been manufacturing Printed Circuit Board Assembly for 15 years.

Driven by our expert production operators; Inno Cables has manufactured Printed Circuit Board Assembly for the following industries:

- Computer and computer installations

- Panel displays

- Lighting systems

- Automotive systems

- Surveillance and navigation

- Manufacturing equipment and machinery

- Robotic systems

- Telecommunication equipment

- Aerospace electronics

At Inno Cables we go above and beyond to guarantee the quality of our Printed Circuit Board Assembly:

- Bespoke Electrical & Directional Testing Service

- Final Quality Control Checks

We offer the following Printed Circuit Board Assembly services:

- Design Improvements

- Sourcing of Material

- Prototyping

- Test

- Kitting

Standards

- IPC/WHMA-A-620

Our Advantages

Flexibility

We are able to provide customized solutions to meet your specific requirements, including unique designs, materials and configurations.

Quality

Standards

Speed

Competitive Pricing

Customer Service

If you have any questions?

If you have any inquiries or need more information about our wire harness products and services, please feel free to contact us.