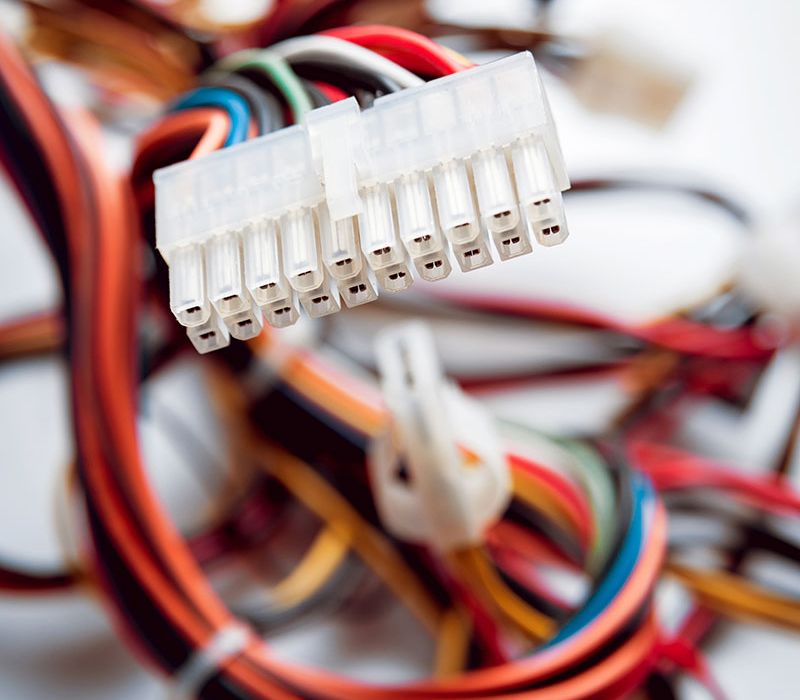

Wiring Harness

Wire harnesses are designed to streamline and organize multi-wire systems in aerospace, automotive, commercial, medical, residential, and telecommunications applications, among others. At Inno Cables, we are proud to offer a broad selection of superior-quality, customized wire harnesses. With more than 15 years of industry experience, our expert team can create a wire harness solution tailored to nearly any specification while ensuring the highest level of precision and care.

The Components of Custom Wire Harness

Terminal Position Assurance

LED Lamp

Panel Mount Push Button Switch

Cable Strain Relief

Push Mount Cable Tie

Axial Cooling Fan

Multi Conductor Cable

Wire to Board or Wire to Wire Connector

Assembly Label

Quick Disconnect Terminals

Our Wiring Harness Capabilities

Depending on your needs, we offer various insulator materials:

- Cellular (foam) polyethylene

- Cross-linked polyethylene (XLPE)

- ECTFE Halar

- ETFE Tefzel

- Ethylene propylene diene monomer (EPDM)

- Fluorinated ethylene propylene (FEP)

- Irradiated polyvinyl chloride (IRR/PVC)

- Low-density polyethylene (LPDE) and high-density polyethylene (HDPE)

- Low-smoke plenum copolymer

- PVDF Kynar

- Polyethylene (PE)

- Polypropylene (PP) and cellular (foam) PP

- Polytetrafluoroethylene (PTFE)

- Polyurethane (PU) and polyurethane and nylon blends

- Polyvinyl chloride (PVC)

- Semi-rigid polyvinyl chloride (SR-PVC)

- Tetrafluoroethylene (TFE)

- Thermoplastic elastomers (TPE/TPR)

- Vinyl

Custom shielding and heat-shrink coatings

Custom labeling/barcoding, four-color ink stamping, independent circuit IDs, and individual tagging

Paper, nylon, and polypropylene

IPC/WHMA-A-620, military, UL, and other applicable standards

Our Wiring Harness Specifications

Understanding the Wiring Harness Manufacturing Process

The custom cable manufacturing process consists of four main stages

-

Design. In the design phase, designers and engineers work closely with customers to outline their needs and constraints. These requirements and restrictions are used to create and digitally test potential designs.

-

Prototyping. In the prototyping phase, physical models of potential cable assembly designs are created. These units are used to test for functionality and manufacturability, ensuring they can be made and used as intended.

-

Production and Assembly. In the production and assembly phase, the cable assemblies are manufactured as per the approved final design in the desired volumes. The manufacturing process consists of many steps, including cutting the conductors, establishing their connections, and assembling them into a single wrapped jacket.

-

Testing. In the testing phase, the completed assemblies undergo rigorous testing to ensure they perform safely and effectively. The exact tests depend on industry and application requirements.

At Inno Cables have been manufacturing Wiring Harness for 15 years.

Driven by our expert production operators; Inno Cables has manufactured Wiring Harness for the following industries:

- Agriculture

- Automotive

- Climate Control

- Radiator and Boiler

- Renewable Energy

- Telecommunication

- Rail

- Oil and Gas

- Energy

- Electronics

- Measurement and Test

- Seating

- Medical

We offer the following Wiring Harness services:

- Design Improvements

- Sourcing of Material

- Prototyping

- Test

- Kitting

At Inno Cables we go above and beyond to guarantee the quality of our Wiring Harness:

- Bespoke Electrical & Directional Testing Service

- Final Quality Control Checks

Standards

- IPC/WHMA-A-620

Our Advantages

Flexibility

We are able to provide customized solutions to meet your specific requirements, including unique designs, materials and configurations.

Quality

Standards

Speed

Competitive Pricing

Customer Service

If you have any questions?

If you have any inquiries or need more information about our wire harness products and services, please feel free to contact us.