Box Build

OUR BOX BUILD CAPABILITIES

We deliver tailored solutions designed to meet the specific requirements of each of our customers’ needs.

- Mounts and Structural Assembly: Attaching mechanical components, such as chassis, brackets and fasteners, and assembling structural elements, frames or internal supports, including brazing.

- Control Panel Installation: Installing control panels, displays, buttons and switches.

- Wiring and Harnessing: Connecting electrical components, wire harnesses, cables and connectors.

- PCB Integration: Mounting and connecting PCBAs, including soldering or socketing electronic components.

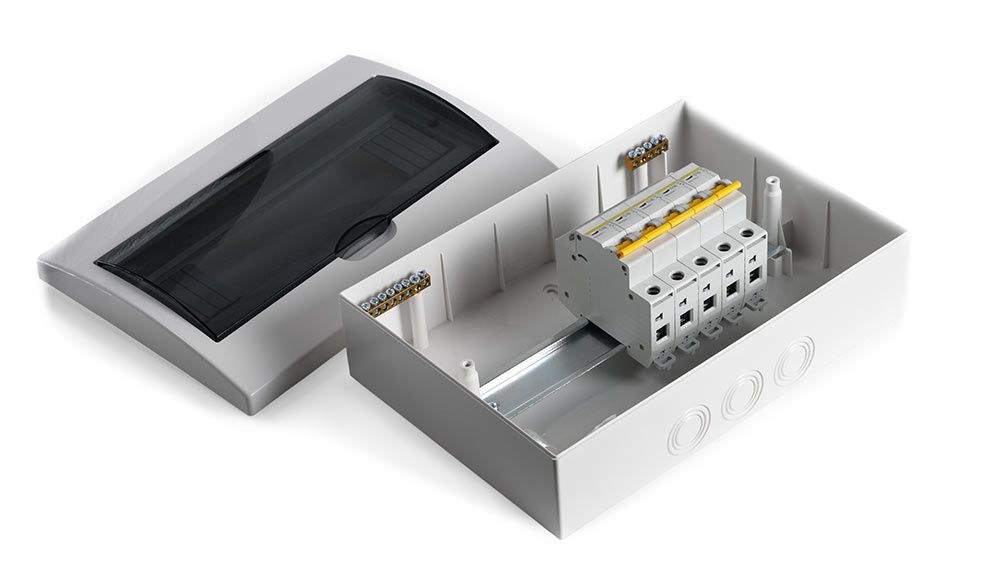

- Power Distribution: Installing power supply units, transformers and circuit breakers.

- Refrigeration and Charging Mechanics: Integrating cooling systems, compressors and refrigerant lines, as well as charging units for optimal thermal management and efficient power delivery.

BOX BUILDS & PANEL WIRING

Here at Inno Cables Manufacturing we provide tailor made electrical box builds and panels for a variety of applications, ranging from electronical control to electrical distribution using only the highest quality components.

Whether your needs are for a singular circuit control or a large scale distribution control here at Inno Cables we can accommodate any order requirements.

We have highly qualified onsite electricians, should you have any specific test and certification requirements.

Understanding the Box Build Manufacturing Process

The custom cable manufacturing process consists of four main stages

-

Design. In the design phase, designers and engineers work closely with customers to outline their needs and constraints. These requirements and restrictions are used to create and digitally test potential designs.

-

Prototyping. In the prototyping phase, physical models of potential cable assembly designs are created. These units are used to test for functionality and manufacturability, ensuring they can be made and used as intended.

-

Production and Assembly. In the production and assembly phase, the cable assemblies are manufactured as per the approved final design in the desired volumes. The manufacturing process consists of many steps, including cutting the conductors, establishing their connections, and assembling them into a single wrapped jacket.

-

Testing. In the testing phase, the completed assemblies undergo rigorous testing to ensure they perform safely and effectively. The exact tests depend on industry and application requirements.

At Inno Cables have been manufacturing Box Build for 15 years.

Driven by our expert production operators; Inno Cables has manufactured Box Build for the following industries:

- Automotive

- Climate Control

- Radiator and Boiler

- Security

- Renewable Energy

- Telecommunication

- Oil and Gas

- Energy

- Electronics

- Measurement and Test

- Medical

We offer the following Box Build services:

- Design Improvements

- Sourcing of Material

- Prototyping

- Test

- Kitting

At Inno Cables we go above and beyond to guarantee the quality of our Box Build:

- Bespoke Electrical & Directional Testing Service

- Final Quality Control Checks

Standards

- IPC/WHMA-A-620

Our Advantages

Flexibility

We are able to provide customized solutions to meet your specific requirements, including unique designs, materials and configurations.

Quality

Standards

Speed

Competitive Pricing

Customer Service

If you have any questions?

If you have any inquiries or need more information about our wire harness products and services, please feel free to contact us.